Organization of a Hazards Analysis

Previous posts in this series have described the different types of process hazards analysis: Creative/Imaginative, Experience-Based, and Logical/Rational. In this series we provide guidance to do with the organization of the analysis.

This post is the first in a paid series to do with the organization and management of process hazard analyses. The following is a list of other posts in this series.

The Leader’s Skills (Part 1)

The Leader’s Skills (Part 2)

The Scribe (this one)

Specialist Support

Sophisticated Language

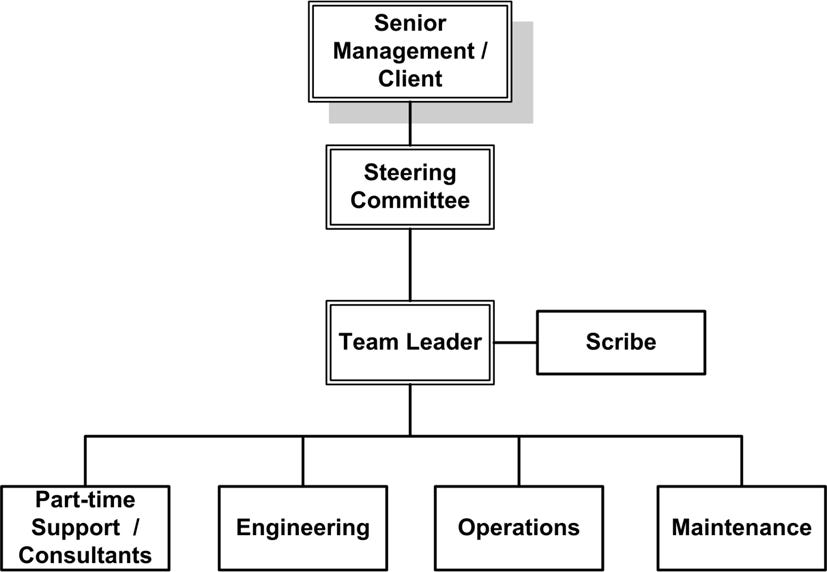

Details as to how the hazards analysis is to be organized will vary depending on the goals of the analysis, the method used and the facility being studied. The organization shown in the sketch is representative.

At the top of the sketch is the senior manager or client who has requested and who is paying for the analysis. The team must understand this person’s needs. For example, some clients just want to be sure that they are in regulatory compliance, others want to identify major events only, and others want a detailed equipment analysis using the Failure Modes & Effects Analysis (FMEA) technique. The PHA must be structured to address the client’s requirements.

Keep reading with a 7-day free trial

Subscribe to The Process Safety Report to keep reading this post and get 7 days of free access to the full post archives.