Washington D.C. October 11, 2024.

The U.S. Chemical Safety and Hazard Investigation Board (CSB) announced today that it is launching an investigation into a fatal release of hydrogen sulfide at the Pemex petroleum refinery in Deer Park, Texas, which occurred yesterday, October 10. Two contract workers died as a result of the release, and an additional 13 workers reportedly were transported to local medical facilities.

Most readers of this blog will be familiar with the hazards of hydrogen sulfide (H2S). Nevertheless, in spite of its familiarity, it useful to review the properties of this dangerous gas. We are publishing a short series of posts

The first two parts of this series are here and here. In this post we consider the toxic effects of H2S. (The information is also provided in the book Plant Design and Operations.)

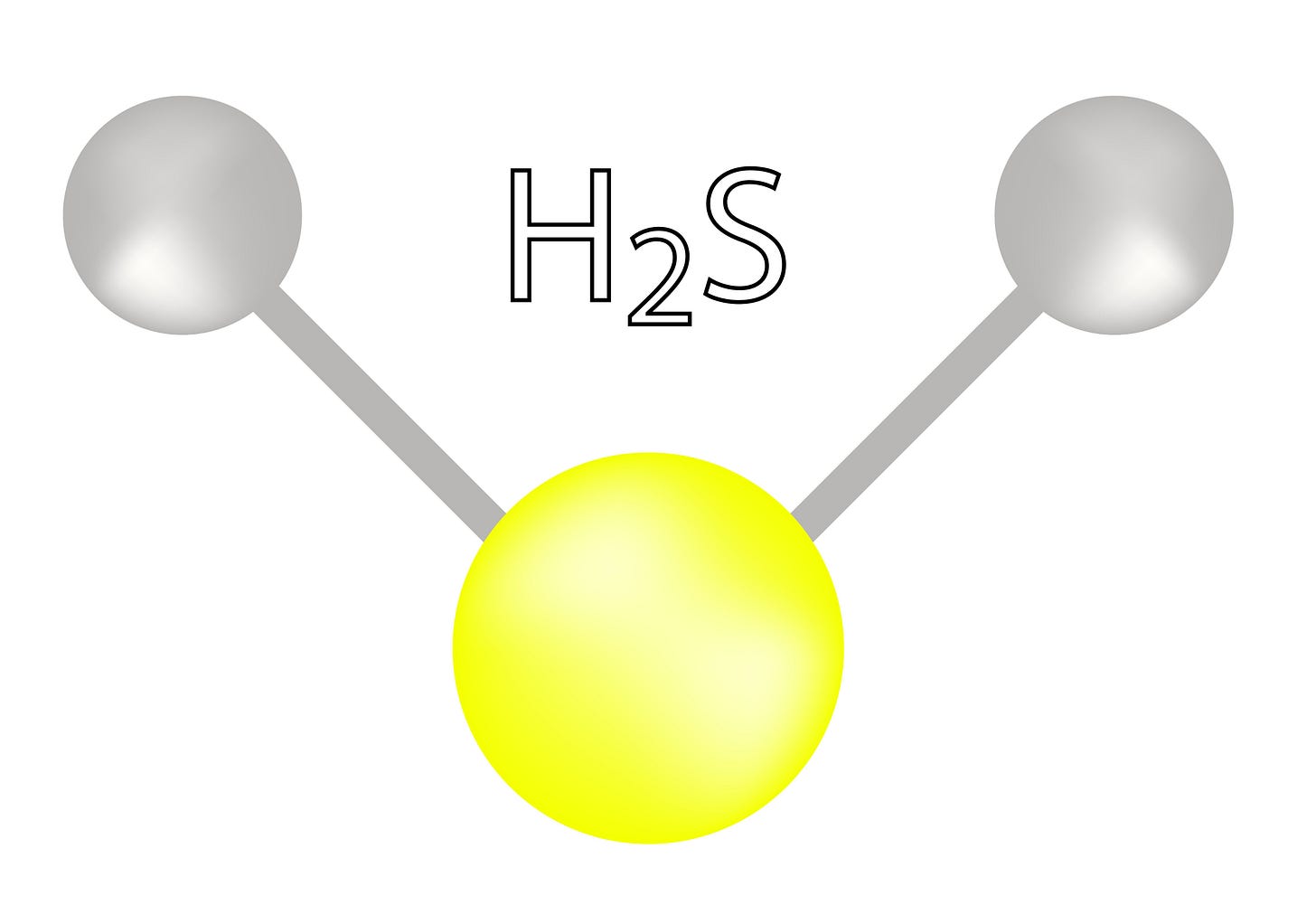

Toxicity

Table 17.5 summarizes the effects of H2S at various concentration levels.

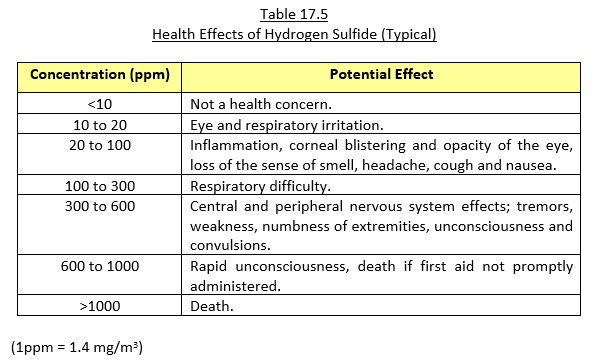

The toxicity of H2S can be seen when measured against other well-known chemicals using Immediately Damaging to Life and Health (IDLH) and Emergency Response Planning Guidelines Level 2 (all values in ppm).

Table 17.6 shows that H2S is only slightly less toxic than hydrogen cyanide — the poison that is so beloved by detective story writers.

H2S oxidizes rapidly in the body; therefore, there are normally no permanent after effects from acute exposure if the victim is rescued promptly and resuscitated before experiencing prolonged oxygen deprivation.

It is not a carcinogen.

Hydrogen sulfide is easily detected by sense of smell up to values of around 100 ppm. But, as stated in a previous post, the sense of smell is unreliable. Moreover, the ability to detect the gas by smell varies widely among individuals. Hence portable H2S detectors are used. Each person who works in an area where H2S may be present carries one of these devices, which is typically set to alarm at a value of 10 ppm. In addition to the personal alarms, fixed sensors located around the facility will warn of a release. These sensors should send a signal to the control room; local visual and audible alarms should be triggered.

Firefighters should always wear H2S PPE when responding to a hydrogen sulfide fire.

Location of Fixed Monitors

API RP 14C provides the following guidance for the location of fixed H2S monitors for offshore installations. It also provides useful guidance for onshore operations. The following guidance should be considered.

Atmospheric H2S concentration is > 50 ppm;

H2S concentration in piping is > 100 ppm;

Enclosed areas as defined by API RP500 where H2S could reach >50 ppm;

Poorly ventilated areas;

Sensors should be no greater than 1 meter above the floor/deck with a grid pattern of at least one detector per 40 m2 of floor space;

Sleeping quarters.

Within 3 meters of applicable equipment:

Vessels

Compressors (>50HP/38 KW should have two monitors)

Pumps

Headers

Wellheads

Sensor Technology

Personal H2S monitors can use one of two types of technology. The first is based on electrochemical sensors. It is the most commonly used technology because the monitors are small in size and have a low power consumption. They are, however, subject to degradation and may not be accurate and extremes of temperature and humidity. An alternative technology is the use of semiconducting metal oxide (SMO) sensors. They have fast response times and can operate accurately in harsh conditions. However they use more power than the electrochemical type. Therefore, they are more applicable for installed sensors rather than portable devices.