Safe Limits

Earlier this month the U.S. Chemical Safety Board (CSB) issued its report Fired Heater Tube Rupture and Fire at Marathon Martinez Renewables Facility. The CSB identified the following six process safety issues.

Safe Operating Limits;

Worker Proximity to Fired Heater;

Low Flow Through Fired Heater;

Burner Operation;

Valve Misalignment; and

Corporate Oversight

As time permits, we will work through each of these items. In this post we look at the first item in the CSB’s list: Safe Operating Limits.

Safe Operating Limits

The CSB report states,

Marathon’s corporate standards required “Normal Operating Limits” and “Not-to-Exceed” limits for various operating parameters. Marathon’s corporate standards required alarms on Normal Operating Limits and Not-to-Exceed limits to trigger operator response

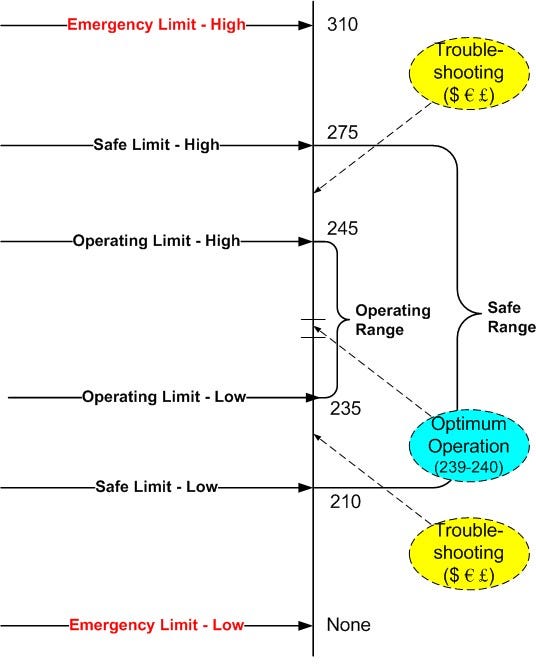

In our upcoming book Process Safety Management, we suggest that there should be three limit values, as shown in the sketch:

Operating limit,

Safe limit, and

Emergency limit.

For each limit a quantified value is required.

The catch is that it is difficult to determine what the limits are without triggering an event, or without falling into a circular logic trap. how these dilemmas are described in the book.

Finding the Safe Limits

Although a knowledge of safe limits is foundational to any successful process safety program, it is not easy to determine what those limits are. For example, management may be able to increase production rates if the temperature of the reaction is increased. However, as the temperature increases there is a chance that the reaction could become uncontrollable and cause a runaway reaction. In this situation, no responsible manager will deliberately increase the reaction temperature to find out what that threshold temperature may be. (The accident at the Chernobyl nuclear power plant provides an exception to this statement. At that facility management deliberately tested the safe limits of the system; they paid the price.)

The challenge to do with determining safe limits is particularly important when conducting a Process Hazards Analysis (PHA). Regardless of the process variable that is being evaluated, the discussion tends to founder on Catch-22 questions such as the following.

Could high temperature cause an accident?

What is high temperature?

It is the temperature that could cause an accident.

If the facility being evaluated has been in operation for a few years it is possible that experienced team members will recall near misses that they have experienced. This experience will help set the safe limits.

If the facility is still in the design stage, then identifying the safe limits becomes particularly challenging. However, the concept of RAGAGEP (Recognized and Generally Accepted Good Engineering Practice).