Most Process Safety Management (PSM) regulations, standards and publications are oriented toward static facilities such as offshore platforms, oil refineries and chemical plants. Yet there is one industry that handles a wide variety of highly hazardous chemicals in bulk that does not formally implement process safety programs ― and that is the railroad industry.

Naturally, freight railroads do have active and vigorous safety programs, not least with regard to railroad crossings. But those programs tend to focus on railroad technology and on occupational safety. Yet there are opportunities for applying the principles of process safety to the rail transportation of chemicals and fuels. In this series of posts we will consider how this can be done. We will structure the discussions around the 20 elements of process safety, as defined by the CCPS (Center for Chemical Process Safety). They are:

Process Safety Culture

Compliance

Competence

Workforce Involvement

Stakeholder Outreach

Knowledge Management

Hazard Identification / Risk

Operating Procedures

Safe Work Practices

Asset Integrity / Reliability

Contractor Management

Training / Performance

Management of Change

Operational Readiness

Conduct of Operations

Emergency Management

Incident Investigation

Measurement and Metrics

Auditing

Management Review

Let us start by considering a high profile accident that took place last year.

East Palestine Accident

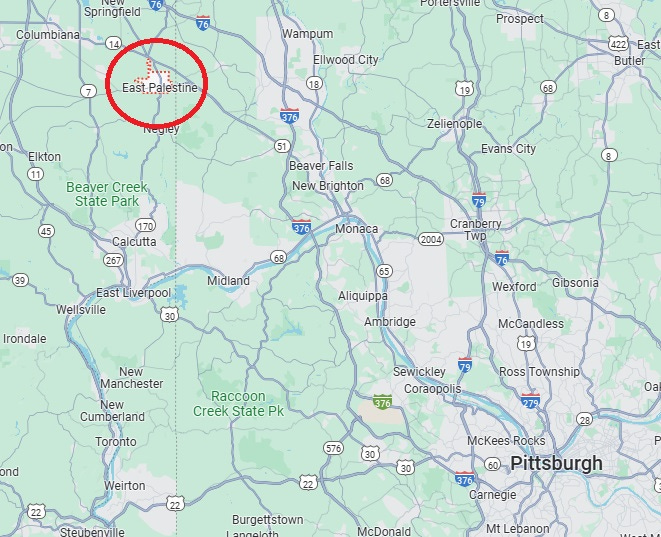

One of the most serious accidents involving highly hazardous chemicals and freight railroads occurred on February 3, 2023 near the town of East Palestine, Ohio ― about 50 miles from Pittsburgh, PA. No one was injured, nor were there any fatalities. However, the decision to vent and burn the contents of the vinyl chloride monomer cars had a serious environmental impact.

The National Transportation Safety Board has published a 13-page Abstract of its report to do with the accident. In this and subsequent posts we will review that that Abstract to see what process safety lessons can be learned.

Senate Bill S.576

Following the East Palestine accident, Senator Brown of Ohio introduced Senate Bill ‘S. 576. To enhance safety requirements for trains transporting hazardous materials, and for other purposes.’

The proposed Bill states in part,

. . . the Secretary shall issue regulations, or modify existing regulations, establishing safety requirements, in accordance with subsection (b), with which a shipper or rail carrier operating a train transporting hazardous materials that is not subject to the requirements for a high-hazard flammable train under section 174.310 of title 49, Code of Federal Regulations, shall comply with respect to the operation of each such train and the maintenance of specification tank cars

The bill has not yet passed the Senate or the House.

Communications Failure

A first reading of the report highlights the fact that communications failure was a common cause in this event. These failures include:

Five of the tank cars contained vinyl chloride monomer (VCM). These cars were damaged, but they did not leak. The VCM was stabilized, which meant that it would not have polymerized if the cars been exposed to external fire. Had the incident commander been fully aware of this fact, it is likely that he would not have authorized the vent and burn response that created the environmental damage.

This misunderstanding was exacerbated by the fact that the Chlorine Institute’s Pamphlet 171 ‘included misleading information about signs of polymerization’.

Moreover, ‘the absence of Oxy Vinyls’ expertise from the formal incident command denied the incident commander relevant information necessary to make a fully informed decision about the vent and burn.’

Flammable chemicals from other cars did leak and catch fire. The fire made some of the railcar placards illegible.

Information about the hot wheel bearing was not conveyed to the train crew.

‘Because there were not common radio channels between all the reporting agencies, the emergency response lacked sufficient coordination’.

All but the last of these items fall under CCPS Element #6 ― Knowledge Management, with the key word being ‘management’. With the possible exception of the Chlorine Institute pamphlet, accurate and relevant information was available, but it had not been effectively communicated to the incident commander.

Other Chemicals

The NTSB report notes that the emergency responders did not have sufficient information to do with vinyl chloride and its stabilization. But the Abstract of the report does not consider the fact that the trains that crisscross haul an enormous number of chemicals, many of which are more hazardous than vinyl chloride.

It is unrealistic to expect the local emergency responders to have immediate access to all of the specialized information that they are likely to need in real time, even within the three days that the incident commander had in this situation.

One of the recommendations in the report reads as follows,

We recommended that the Association of American Railroads develop a database of bearing failure and replacement data to help railroads, regulators, and investigators identify and address bearing failure risk factors.

Another recommendation on the same lines could be,

We recommend that the American Institute of Chemical Engineers develop a database of safety data sheets and emergency response guidelines for chemicals being moved by rail. This data base will provide real-time guidance to emergency responders.

This would seem to be a possible application of Artificial Intelligence technology.