Inherent Safety: Simplify

We continue our series of posts on the topic of Safety in Design. The first eight posts were,

Inherent Safety: Moderate.

The principles of inherent safety vary from organization to organization, but most descriptions of the topic are structured around the following five elements.

Eliminate

Substitute

Minimize

Moderate

Simplify

In this post we consider the final item in the above list: Simplify.

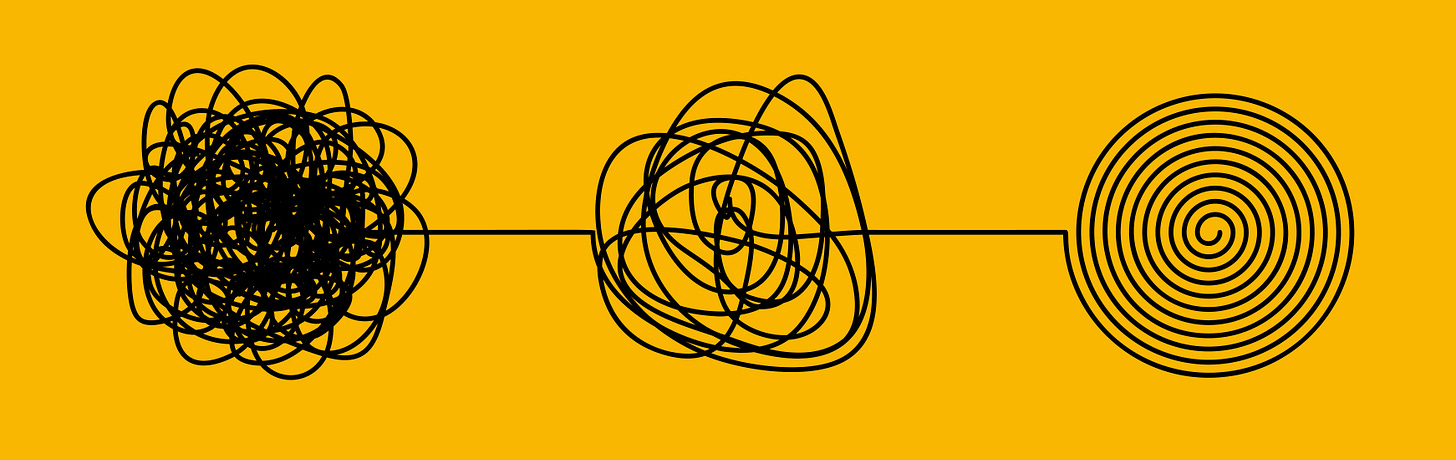

The final step in achieving Inherent Safety is to make systems as simple as possible. Simplification makes a system more error tolerant and improves overall reliability. And, if things do go awry, the operators will probably have a better grasp of the situation.

Simplification usually involves reducing the complexity of systems or processes. designs to minimize the likelihood of errors, malfunctions, or accidents. For example, a facility may have two chemical reactors operating in parallel. The process can be simplified by replacing these reactors with one larger unit. Doing so reduces the chances of leaks and operating errors.

Some simplification steps may turn out to be counter-productive. Using the two reactor example once more, if the company has to reduce production rates for economic reasons there may be a minimum flow rate below which the single reactor cannot operate safely.

Simplification may also be achieved by moving away from complex, instrument-based control and safety systems. Manual operations are not necessarily less safe operations.

Your author once worked on a process plant that manufactured ethylene oxide ― a material that is both toxic and highly flammable. Before being used in a downstream process, the product was stored in intermediate storage tanks. These tanks had no level instrumentation at all. The operator’s job was to climb to the top of the tank at regular intervals and measure the level with an old-fashioned strapping gauge. A process safety analysis called for level instrumentation, including at least one high level alarm, to be installed. Yet there had never been an overflow of product over the course of many years of operation. The lack of incidents provided grounds for challenging the need for additional instrumentation.

One area of potential simplification involves written procedures and training. As we saw in Operating Procedures - The Basics, operating procedures are often unnecessarily complex and poorly written. They offer an excellent opportunity for improved simplification. Similarly with training. Simplified training materials and presentations are easier to comprehend and remember.