Equipment Spacing (Pumps/Pipe Racks)

Pump seals are a source of leaks in process and energy facilities. The discharged liquid will normally be at high pressure, so it can travel a long distance and/or form a spray. Therefore, when laying out a facility it is important to make sure that pumps are located at a safe distance from other equipment and piping. (If the facility is already constructed and in operation it is still useful to consider spacing and layout guidelines. If some items are too close to one another there may be a justification for installing additional safeguards such as more fire-fighting equipment, a deluge system or firewalls.)

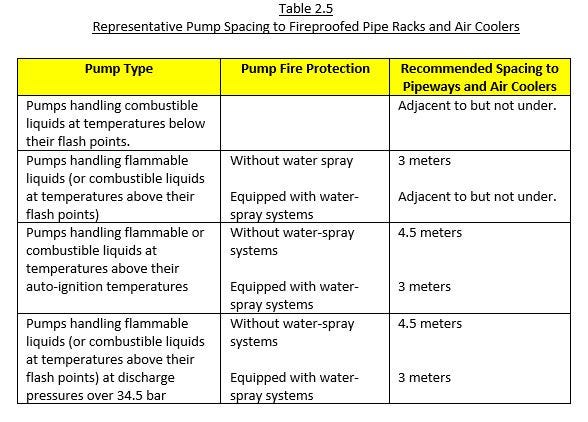

The Table below, which is taken from the book Plant Design and Operations, provides guidance as to the safe spacing of pumps from fireproofed pipe racks and air coolers. (Air coolers are a hazard because they the leaked material can be pulled into their suction and then vaporized and dispersed over a long distance.)

Naturally, before making decisions as to layout and spacing in specific situations, it is necessary to consult the regulations, engineering standards and company standards that apply to that situation and location. Also, in some situations, vapor dispersion analysis may be justified.

Further information on this topic is provided in the book Plant Design and Operations.