AI: Analysis of a CSB Report

An earlier post today discussed the use of Artificial Intelligence as a tool in the Process Safety discipline.

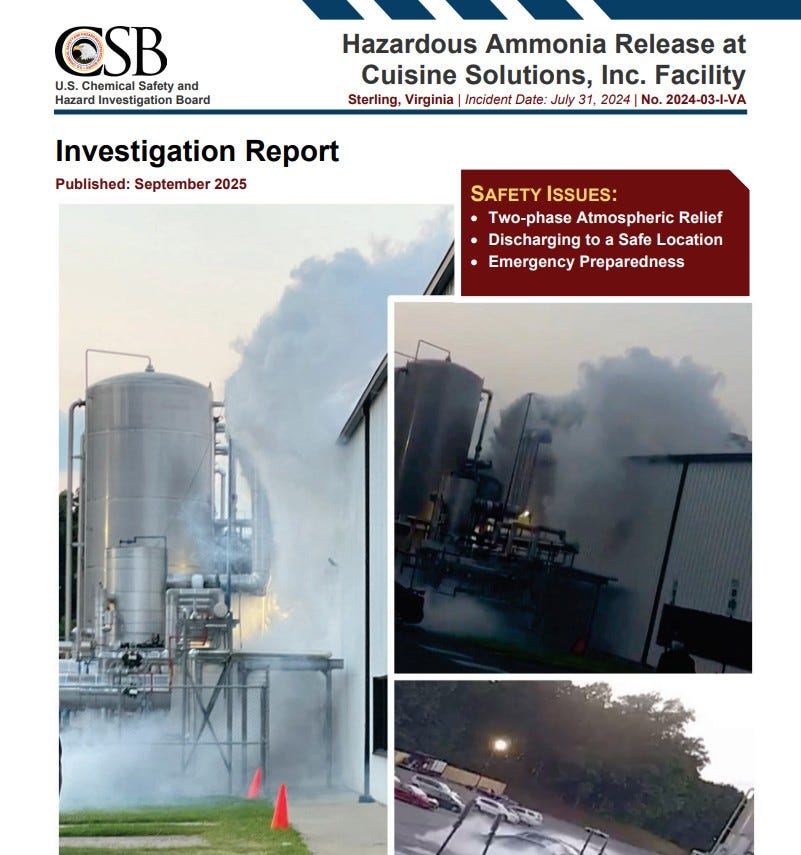

One area where AI can be helpful is in analyzing publicly available incident reports. To test this principle, I decided to test a Chemical Safety Board (CSB) report, Hazardous Ammonia Release at Cuisine Solutions, Inc. Facility, that was published yesterday. I have found these reports to be very well researched, but their findings often seem to be too narrow. For example, the Cuisine report focuses on the hazards to do with ammonia, but it does not provide quick guidance to someone in a totally different industry ― say an offshore oil and gas platform.

Cuisine Solutions Report

I entered the following prompt into ChatGPT.

The reports published by the Chemical Safety Board (CSB) provide useful insights. However, I find that the findings tend to be too specific. For example, the report just released to do with the ammonia release at Cuisine Solutions, Inc. provides detailed findings and recommendations to do with ammonia. But the report does not provide much guidance to a manager working in another industry, such as offshore oil and gas.

Please review the attached report and develop general recommendations using the 20 elements of the CCPS guidelines. Do not cite an element if it does not seem to be relevant.

<Note: ChatGPT knows what the CCPS elements are. However, I list them below for those who may not know them in detail.

Process Safety Culture

Standards, Codes, Regulations, and Laws

Process Safety Competency

Workforce Involvement

Stakeholder Outreach

Process Knowledge Management

Hazard Identification and Risk Analysis

Operating Procedures

Safe Work Practices

Asset Integrity and Reliability

Contractor Management

Emergency Management

Incident Investigation

Management of Change

Operational Readiness

Conduct of Operations

Training and Performance Assurance

Process Safety Metrics

Continuous Improvement

Process Safety Leadership. >

Reply

Here is the reply.

I’ve reviewed the CSB report on the ammonia release at Cuisine Solutions and extracted the broader lessons that can be applied across industries. Below is a set of generalized recommendations framed around the CCPS 20 Elements of Process Safety. I’ve only included elements that clearly connect to the issues raised in the report.

1. Process Safety Culture

Promote a culture where activating emergency shutdowns or alarms is encouraged and supported, rather than delayed by hesitation or fear of disruption.

Leaders should reinforce that protecting people and the environment takes precedence over production continuity.

2. Compliance with Standards & RAGAGEP

Ensure design and operations align with recognized and generally accepted good engineering practice (e.g., API 521 for relief systems, IIAR/ANSI standards for refrigeration).

Regularly benchmark against both industry-specific and cross-industry standards.

3. Process Safety Information (PSI)

Maintain accurate information on relief devices, shutdown systems, and emergency safeguards.

Establish data historians and monitoring tools so that critical process data are recorded, analyzed, and available during and after incidents.

4. Process Hazard Analysis (PHA)

Evaluate credible overpressure, release, and two-phase discharge scenarios—not just single-phase vapor assumptions.

Incorporate building wake effects, discharge orientation, and local geography into dispersion and consequence analyses.

5. Operating Procedures

Procedures must explicitly cover system-wide emergency shutdowns, with clear roles assigned.

Include instructions for indoor vs. outdoor release scenarios, shelter-in-place decisions, and alternate evacuation routes.

6. Training & Performance Assurance

Train multiple employees to perform critical tasks such as using emergency shutdown devices.

Use drills that realistically simulate toxic release scenarios, not just fire emergencies.

7. Mechanical Integrity

Audit relief systems to ensure all credible scenarios are identified, and that devices are inspected, tested, and replaced per schedule.

Confirm that relief discharges route to safe locations.

8. Management of Change (MOC)

Apply MOC to modifications in relief systems, shutdown logic, alarms, or evacuation plans.

Consider automation of shutdowns when feasible, while ensuring manual fallback options remain.

9. Emergency Management

Update Emergency Action Plans to address distinct scenarios (indoor vs. outdoor releases) with appropriate alarms, routes, muster points, and PPE.

Implement distinctive alarms for toxic releases vs. fires.

Conduct annual release drills involving all staff, including contractors and corporate employees.

10. Incident Investigation

Capture sufficient process data to reconstruct events; otherwise, root causes may remain uncertain.

Share findings across sites and industries, not just within the affected facility.

11. Auditing

Use third-party audits to validate relief system design, maintenance practices, and emergency planning.

Audit the completeness of implementation for all PSM elements, closing gaps promptly.

12. Stakeholder Outreach

Coordinate with local responders on toxic release scenarios, not just fires.

Ensure communication systems (alarms, public notifications) reach both employees and nearby communities.

These recommendations draw from the CSB’s findings but are framed so that a manager in offshore oil & gas, refining, or chemicals can apply them without reference to ammonia-specific details.

Conclusions

The insights of ChatGPT are broadly applicable to a wide range of industries. In this example, AI was able to provide practical help to managers and other professionals working in the energy and process industries.